Search

Top 10 Equipment Rental Companies in India

For many businesses, renting equipment offers a cost-effective and flexible solution.

Lifting India’s Future

As India builds faster and taller, industrial cranes are emerging as essential, intelligent machines powering the nation’s infrastructure, logistics, and industrial growth.

Lifting India’s Future

As India builds faster and taller, industrial cranes are emerging as essential, intelligent machines powering the nation’s infrastructure, logistics, and industrial growth.

“Financial management a challenge in rental industry.”

Siddharth Sharma, Director, Premier Heavy Lift, speaks on the current landscape of the construction equipment rental market in India.

Maximising Uptime

India bearings market is projected to reach $6714.8 million by 2032, growing at a CAGR of 13.5 per cent from 2024 to 2032.

Financial management a challenge in rental industry

Premier Heavy Lift (PHL) stands as a leading force in the heavy lifts and transportation sector, marked by excellence in quality, safety, and innovative practices under the leadership of Anil Chaudhary, Som Dutt Sharma and Capt Sandeep Anand. Since its inception with merely two cranes, PHL has evolved dramatically, boasting a fleet of over 360 equipment units valued at more than Rs 900 crore. Siddharth Sharma, Director, Premier Heavy Lift, speaks on the current landscape of the construction equipment rental market in India.

MYCRANE makes strides in critical Indian market

MYCRANE, the world’s first global platform for online crane rental, has seen a surge in new client registrations and project enquiries in the booming Indian market.

Business booming in India as MYCRANE platform makes strides in critical market

Lifting equipment sourced via MYCRANE deployed on pan-India basis

Safety at New Heights

Mobile cranes are relatively easier to operate, manoeuvre, and optimise. However, they are highly prone to accidents.

Enhancing efficiency

India’s construction equipment market is growing quickly, and this is stimulating demand for bearings. The bearing industry is expected to grow at a rate of 9 to 10 per cent in the years ahead.

We are well known in the field of manufacturing crane safety systems

Vijay Tikhe, Partner, Cranesafe Technologies, speaks on the present scenario regarding crane safety systems in India.

On the Move!

The market for mobile cranes is on the move driven by low-rise residential, commercial, and industrial building construction activity in urban areas.

Liebherr mobile construction crane in electric operation

The Liebherr MK 88 Plus has been in service at Krandienst Kunze since April 2019

Tiong Woon adds Grove GMK6300L-1 crane

Tiong Woon Crane & Transport recently added a Grove GMK6300L-1 to its fleet and has deployed it to lift replacement parts at Shell Jurong Island, Shell?s largest refinery in the Asia-Pacific region.

Liebherr to supply armoured mobile and rescue cranes to German Army

Liebherr-Werk Ehingen GmbH received an order from the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) to deliver a total of 71 armoured mobile and recovery cranes worth around EUR 150 million.

FROM RECOVERY TO GROWTH

The construction market in India is the second largest in Asia-Pacific Countries (APAC) region and is expected to become the fastest growing market in the region by 2025.

Facilitating efficiency

Bearings fulfill a number of important functions, starting with their ability to reduce friction. Other primary functions include supporting a load, promoting the efficient transmission of power and ensuring alignment is maintained.

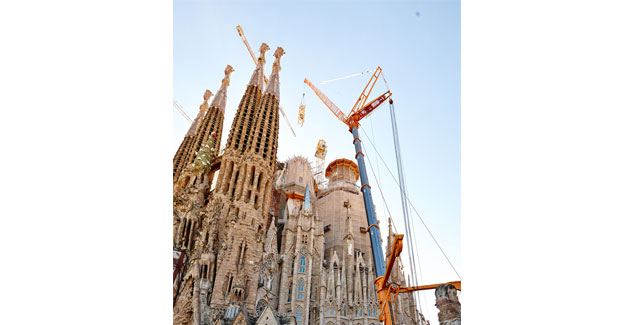

Liebherr crane moves construction crane in Barcelona

Spanish crane contractor Gr?as Rigar used a Liebherr LTM 1500-8.1 telescopic crane to relocate one of the three massive construction cranes at the Sagrada Familia in Barcelona.

Wind power, Metro and refineries will spur demand

At present, demand for cranes is mixed. The cranes which are engaged with RIL Jamnagar for the past 2-3 years are gradually de-hiring and majority of them are getting engaged in windmill segment. Demand from other segments like thermal power, steel, cement, infrastructure, refinery etc is subdued.

Liebherr mobile crane relocates massive construction crane in Barcelona

Spanish crane contractor Gr?as Rigar used a Liebherr LTM 1500-8.1 telescopic crane to relocate one of the three massive construction cranes at the Sagrada Familia in Barcelona.

Safety in Mobile Cranes

Do you plan to buy new safety system for your mobile crane? There are a number of safety systems of various brands available in India. Do all these brands really protect your crane from all unsafe conditions? Have you ever thought that your retrofit system manufacturer provides all the options provided by the crane data?Most of the systems manufacturers show basic data like boom length, boom angle, load signal etc.

Integrated Load Handling Solutions

With a myriad of attachments, truck-mounted cranes have created niche applications segments with faster, safer and more productive solutions.Construction industry has been witnessing a shift towards using safer, more advanced technology, especially application-oriented equipment and machinery

STILL Number One

The focused thrust on infrastructure, manufacturing and agricultural sectors is expected to boost the demand for pick-n-carry cranes, which dominate the mobile crane market with over 80 per cent of total sales.

Achieving Cost Efficiency

Cost efficiency is not only achieved through cleaner engines, but also through optimising the man-machine interface with a variety of machine control technologies, 'correcting' the usage patterns, and packaging solutions that take care of clients' business needs around project costs.

Heavy Lift for IOCL Refinery

Allcargo successfully completed major heavy lifts for Indian Oil Corporation?s (IOCL) refinery at Paradip in Odisha.The projectHeavy lifts for IOCL refinery at Paradip, Odisha. One of critical job was to erect a 1,200 tonne vessel of 144 ft length and various other heavy lifts. The project mandate was to erect a 1,200T vessel of 144 ft in length and various other heavy lifts.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com